OS7 STONE SLINGER

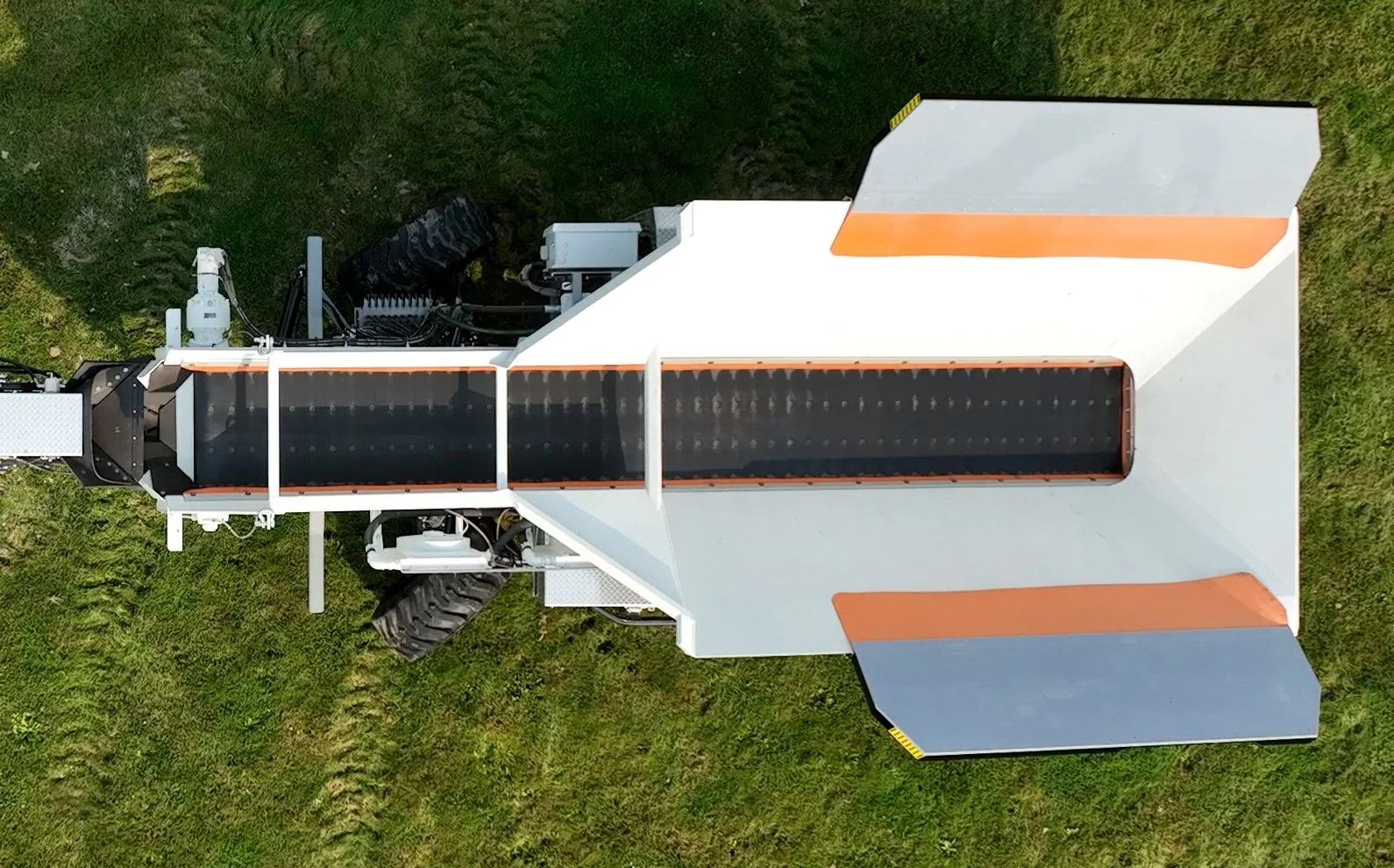

Introducing the Self-propelled OS7 by WK Dahms - a game-changer in the realm of large-scale construction projects. Designed to deliver unparalleled efficiency and productivity, the OS7 empowers operators to achieve non-stop, remote-operated material placement of up to 400 tons per shift. With seamless integration into your workflow, this cutting-edge machine redefines the way materials are distributed on-site.

Featuring a high-speed conveyor system with its own hydrostatic, four-wheel drive platform the OS7 ensures precise positioning and smooth operation, allowing for swift and accurate material placement. By enabling operators to feed the hopper directly from on-site stockpiles using available loaders, the OS7 eliminates downtime and optimizes workflow, ensuring a continuous supply of materials for uninterrupted progress.

PRODUCT FEATURES

“LIVE BOTTOM” APRON FEED CONVEYOR

The live bottom conveyor eliminates gates, beams and the issues associated with them. Powered by a robust planetary drive, the live bottom system off-loads smoothly to the conveyor belt.

HIGH PERFORMANCE PLACING CONVEYOR

The OS7 utilizes high performance hydraulics on the placing conveyor to reach throw distances of 120 ft. 250º working pivot radius and an increased angulation of 23º above and below horizontal, operators have complete control for precise placement.

ALL TERRAIN MOBILITY

Hydraulic hopper levelling keeps the machine stable on uneven terrain. Rugged, high flotation tires and high torque drive systems tackle the toughest jobsites with ease.

REMOTE OPERATION

Wireless remote control of all Stone Slinger functions including hydrostat drive and individual axle steering control to navigate tight jobsites. Also includes remote engine start and stop.

HOPPER WING EXTENSIONS

Individually operated, hopper wing extensions allow for loading via large bucket loaders. This reduces material spillage and waste. Wings can be left in the lowered position which allows for easy side loading.

HOPPER CAPACITY

7 cu/yd

SPECIFICATIONS

BASIC BODY DIMENSION

Body (LxWxH): 260” x 102”’ x 108”

Loading Height: 74”

Net Weight: 18,600 lbs (8437 kg)

DRIVE SYSTEM

CAT C4.4TA (Tier 4F) 131 HP, fuel efficient self-contained diesel power with direct coupled hydraulic pumps

Engine and system control via Sauer Danfoss CANBUS

Danfoss closed loop piston pumps and motors on drive system

Danfoss variable displacement pumps and load sense valves on Stone Slinger functions

Planetary gearbox with direct coupled hydraulic motor on swing frame for conveyor rotation

4 steering modes controlled via transmitter ~ front, rear, articulated & crab

CONVEYOR PLACEMENT SYSTEM

32” apron chain centers, 26” wide live-bottom unloading system

19’ throw conveyor c/w W.K. Dahms ½” high cleat belt

STANDARD FEATURES

Super-Shield™ Power Drive matches conveyor speed for improved control

Double pivot swing frame with 250° degree working pivot radius

Low overall profile to access indoor work sites

Hopper wing extensions reduce material spillage and waste; feed with larger loaders and excavators