ULTRA STONE SLINGER

Introducing the Ultra Stone Slinger - an industry-preferred, precision material delivery system by WK Dahms. The Ultra Stone Slinger is meticulously designed to provide precise placement of materials such as dirt, mulch, topsoil, aggregates, and sand with labor-free efficiency, reducing construction time, and minimizing clean-up.

Available in multiple sizes, the Ultra Stone Slinger can accurately place materials up to 100 feet from the end of the truck, eliminating the need for re-handling material. Its durable and robust build ensures safe, reliable, and long-lasting performance.

The Ultra Stone Slinger is built to order, with options to suit specific needs, and can be customized through WK Dahms' engineering services for unique and specialized solutions.

WATCH IT IN

ACTION

PRODUCT FEATURES

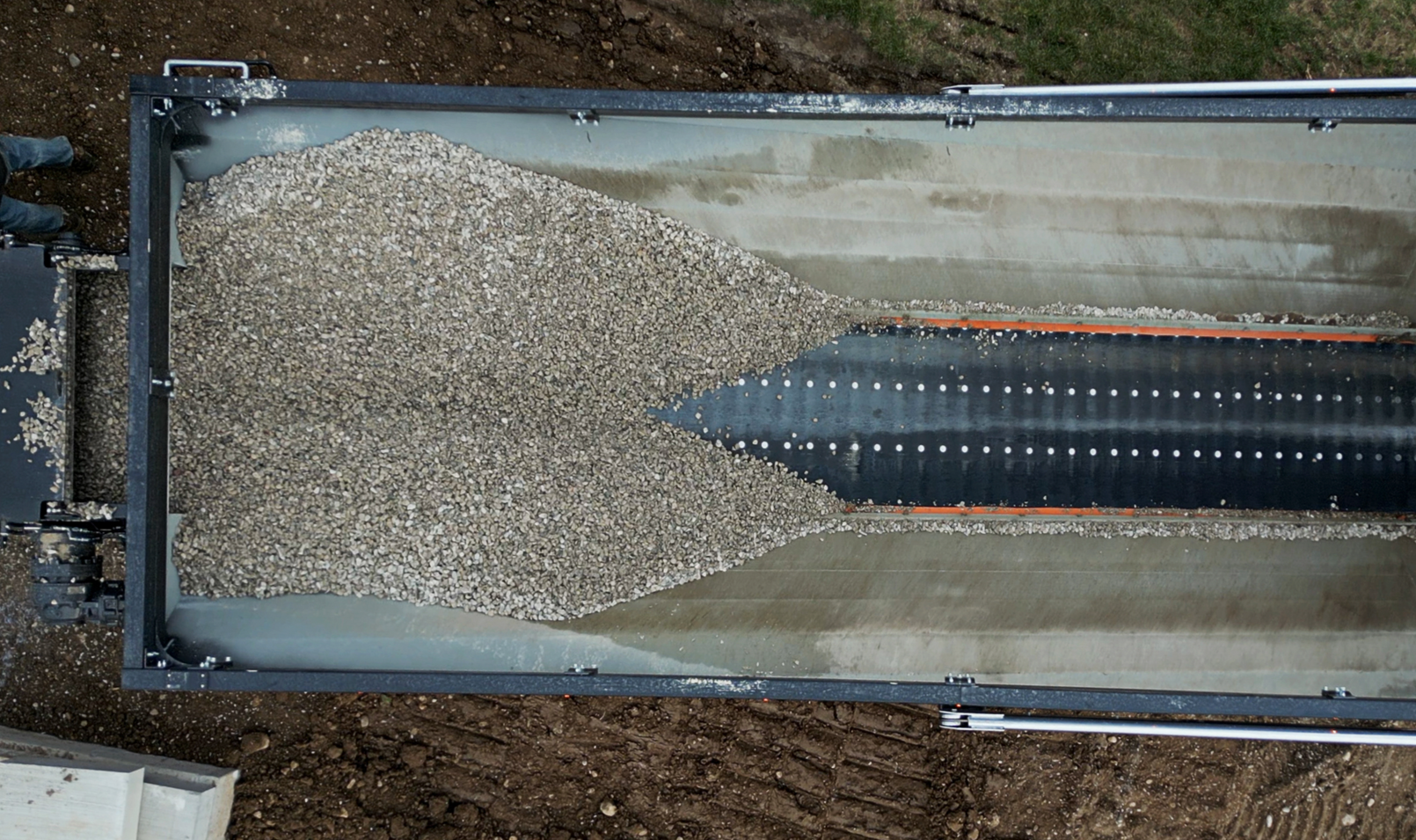

LIVE BOTTOM CONVEYOR

The live bottom conveyor eliminates gates, beams and the issues associated with them. Powered by a robust planetary drive, the live bottom system off-loads smoothly to the conveyor belt.

SUPER-SHIELD™

The Super-Shield™ Power Drive matches the conveyor belt speed to improve control of material on the belt and allow precise delivery, even to those difficult to reach areas up to 100 ft. away.

CONVEYORS/PRECISION

With a 250º working pivot radius and an increased angulation of 23º above and below the horizontal, operators have complete control for precise placement up to 100 ft.

REMOTE OPERATION

Danfoss IK3 / Plus1-CanBUS proportional wireless remote control with advanced diagnostic capabilities. Complete control of all Stone Slinger functions.

SPECIFICATIONS

| Standard Width Apron Feed Belt | Wide Apron Option Feed Belt | |||||

|---|---|---|---|---|---|---|

| Ultra 16 Click for drawing |

Ultra 18 Click for drawing |

Ultra 20 Click for drawing |

Ultra 16 (Wide) Click for drawing |

Ultra 18 (Wide) Click for drawing |

Ultra 20 (Wide) Click for drawing |

|

| Capacity (Level full top of steel) | 15.4 yd³ | 17.0 yd³ | 18.8 yd³ | 16.2 yd³ | 18.8 yd³ | 20.1 yd³ |

| Capacity (Level full top of wood boards) | 17.9 yd³ | 19.9 yd³ | 21.9 yd³ | 18.7 yd³ | 21.6 yd³ | 23.2 yd³ |

| Net Weight | 9200 lbs | 9500 lbs | 9800 lbs | 9600 lbs | 9900 lbs | 10300 lbs |

| Basic Body Dimensions (L × W × H) | 16 ft × 102" × 85" | 18 ft × 102" × 85" | 20 ft × 102" × 85" | 16 ft × 102" × 85" | 18 ft × 102" × 85" | 20 ft × 102" × 85" |

| "Live Bottom" Apron Feed Conveyor |

|

|

||||

| Ultra 16 Click for drawing |

Ultra 18 Click for drawing |

Ultra 20 Click for drawing |

|

|---|---|---|---|

| Capacity (Level full top of steel) | 15.4 yd³ | 17.0 yd³ | 18.8 yd³ |

| Capacity (Level full top of wood boards) | 17.9 yd³ | 19.9 yd³ | 21.9 yd³ |

| Net Weight | 9200 lbs | 9500 lbs | 9800 lbs |

| Basic Body Dimensions (L × W × H) | 16 ft × 102" × 85" | 18 ft × 102" × 85" | 20 ft × 102" × 85" |

| "Live Bottom" Apron Feed Conveyor |

|

||

Wide apron option feed belt

| Ultra 16 (Wide) Click for drawing |

Ultra 18 (Wide) Click for drawing |

Ultra 20 (Wide) Click for drawing |

|

|---|---|---|---|

| Capacity (Level full top of steel) | 15.4 yd³ | 17.0 yd³ | 18.8 yd³ |

| Capacity (Level full top of wood boards) | 17.9 yd³ | 19.9 yd³ | 21.9 yd³ |

| Net Weight | 9200 lbs | 9500 lbs | 9800 lbs |

| Basic Body Dimensions (L × W × H) | 16 ft × 102" × 85" | 18 ft × 102" × 85" | 20 ft × 102" × 85" |

| "Live Bottom" Apron Feed Conveyor |

|

||

HIGH SPEED PLACING CONVEYOR

14" wide placing belt x 19ft long conveyor frame

HIGH CLEAT high performance, endless placing belt

Variable speed, hydraulic piston motor conveyor drive

Rubber covered, grooved conveyor drive pulley

Super-Shield Power-Drive

Full hydraulic lift and swing conveyor motion, 250⁰ working radius

Conveyor stowing for transport on driver or passenger side (Ultra 16 conveyor stowing passenger side only)

STANDARD FEATURES

Hydraulic vibrator

Engine throttle control

LED lighting throughout, including LED flood/spot work lights

Sliding, arched tarp system

HMW body liner on sloped side walls

CONTROL SYSTEMS

Manual Control - High Mount plus 3 Below - manual control hydraulic valves located at elevated operators platform at rear of Stone Slinger, includes 3 functions at lower location for conveyor movement

Manual Control - Dual Hydraulic - manual control hydraulic valves located at elevated operators platform at rear of Stone Slinger, as well as full control a lower ground location

Wireless Remote Control - Danfoss wireless remote control system with Danfoss PVG control valves with PLUS+1® CanBUS control. Control panel includes HMI diagnostic screen, local control and limp mode operation.

PUMP / PTO

Tandem, cast iron, bushing bearing gear pump, direct mounted to PTO

REPTO (rear engine PTO) pump available

HYDRAULIC SYSTEM

(2) high efficiency, 12VDC, thermostat controlled air-oil heat exchangers

Supply filtration at oil reservoir

High-pressure filtration on wireless remote control units

OPTIONAL FEATURES

2nd Hydraulic vibrator

Optional 2-speed feed motor for high-speed offload

12VDC tarp motor

Flip-over style tarping system, 12VDC

Custom paint (solid and metallic)

CREEP DRIVE wireless, remote control of chassis movement on-site

Aluminum toolbox (various sizes available)

Plastic lightweight hoop-style truck fenders

Stainless steel 16ga, rolled-edge fenders